Introduction

Safety showers and eye/ face washes are required as a risk control in many of the HKUST (GZ) laboratories, workshops, and many workplaces. These emergency flushing facilities for eyes and body must be provided within these work areas where there is the potential for an exposure to the eyes or body with corrosive or injurious substances. As such, they are a form of first aid or emergency response equipment to be used in the event of an accident.

The purpose of this program is to ensure that all safety eye/ face washes and showers supply clean, potable water and are in proper working order. This program describes guidelines for its selection, installation and placement; and procedures for its inspection, testing and maintenance and emergency use.

This program applies to all emergency eyewash or facewash and shower units on HKUST(GZ) campus.

Provision of emergency eye/face wash and showers

Emergency washing facilities are needed where there is a potential for dermal exposure. The need is determined from risk assessment or mandated by local laws and regulation, standards or relevant regulatory authority such as 教育部. These specify where and when to use emergency wash stations. Typical areas requiring emergency flushing units include

- Chemical laboratories, janitor closets, industrial washing facilities, and similar spaces where a hazard of corrosive or injurious substances (including air-sensitive or water-reactive liquids or solids) exists,

- Laboratories or areas where there is a potential for the eyes to be exposed to biological hazards that could lead to infection. Emergency eyewashes are required in facilities working at Biosafety Level 2 (BSL2),

- Mechanical workshop where there is a potential for the eyes to be exposed to physical hazards such as flying chips or dust from sanding or grinding processes or chemical hazard of exposure,

- Storage areas where breakable containers of injurious or corrosive materials (one gallon or more) are handled outside their original shipping cartons,

- Waste accumulation areas that could contain corrosive waste materials,

- Pesticide storage or mixing facilities; acid neutralization tank storage areas; swimming pool water treatment facilities.

These may be supported but not replaced with hand-held drench hoses.

Compliance Standards and References

American National Standards Institute (ANSI)/International Safety Equipment Association (ISEA), the ANSI/ISEA’s Z358.1 standard serves as a benchmark internationally to provide shower, eyewash and facewash guidelines, including:

- Proper design of eyewash stations and showers,

- Commissioning and testing procedures,

- Performance and usage,

- Maintenance of flushing equipment, and

- Employee training.

Other recognized standards and references below are based on the American standard ANSI/ISEA Z358.1 and is essentially replicated with change to the units of measure and some other minor changes

- AS4775:2007 Emergency eyewash and shower Equipment

- AS/NZS 2243:1:2005 Safety in laboratories – Planning and operational aspects

- AS/NZS 2982:2010 Laboratory Design and Construction

- ANSI Z358.1 2014 Emergency Eyewash and Shower Equipment Standard

- GB/T 38144.1-2019《眼面部防护 应急喷淋和洗眼设备 第1部分:技术要求》and

- GB/T 38144.2-2019《眼面部防护 应急喷淋和洗眼设备 第2部分:使用指南》

Emergency eye/ face wash and showers and self-contained eye/ face washes in HKUST(GZ) must meet the requirements of and be installed in accordance with ANSI/ISEA Z358.1 and the HKUST(GZ) Laboratory Facilities Standards (Appendix A).

Types of Emergency Eyewash/Facewash and Shower Equipment

The hazard of the material and nature of exposures determines the suitability of the facility used for flushing a body part and eye/ face. Below are examples of emergency flushing equipment.

- Emergency shower equipment.

- Eyewash equipment.

- Eye/face wash equipment.

- Combination shower and eyewash or eye/face wash equipment.

- Supplemental equipment including drench hoses and self-contained equipment

- Facilities for disabled persons.

Emergency showers (Plumbed) - A device specifically designed and intended to deliver flushing fluid in sufficient volume to cause that fluid to cascade over the entire body. These devices require 20 GPM of flushing fluid at 30 PSI for 15 minutes.

Emergency eye/face washes (Plumbed)

- are required in areas where there is a potential eye or face exposure. Please note standard compliant eyewash stations mounted on sinks or faucets may not be sanitary.

- Approved eyewash stations must deliver at least 0.4 gallons per minute (GPM) of flushing fluid at 30 pounds per square inch (PSI) for 15 minutes.

- Eye and face wash units are designed to flush the operator’s eyes and face simultaneously by delivering a minimum of 3 GPM of fluid at 30 PSI for 15 minutes.

- Plumbed eye/facewash stations may be mounted to (i) a wall; (ii) countertop, (iii) recessed laboratory eyewash/shower cabinets or (iv) a pipe stand referred to as a pedestal mount. Plumbed eyewashes may include a bowl that collects and directs fluid away from the eyewash user after use.

- Swing-down eyewashes that drain into sinks are preferred.

Faucet-integrated or faucet mounted eyewash stations

- These attached to a sink’s faucet. Most faucet-mounted (gooseneck) “eyewashes” do not meet the requirements, principally because they lack quick-opening valves.

- Eyewash installed on a faucet spout is NOT recommended in HKUST(GZ)

Portable stations and Self-contained eyewashes

They are practical in areas or rescue vehicles where no reliable plumbing or water source is available. These are discouraged from being installed on campus in lieu of plumbed eyewashes. These are only supplemental device to plumbed eye/ facewash in the area. These can be:

They are practical in areas or rescue vehicles where no reliable plumbing or water source is available. These are discouraged from being installed on campus in lieu of plumbed eyewashes. These are only supplemental device to plumbed eye/ facewash in the area. These can be:

Pressurized tank eyewash station These stations connect to drench nozzles or a hose. They are extra-portable and useful for immediate emergency operations in most outdoor environments. Use them temporarily in emergencies before getting to a primary eyewash station.

Pressurized tank eyewash station These stations connect to drench nozzles or a hose. They are extra-portable and useful for immediate emergency operations in most outdoor environments. Use them temporarily in emergencies before getting to a primary eyewash station.- Squeeze bottles (Personal eyewashes). These SHOULD NOT be used as a primary eyewash station. They are only to be used in areas where plumbed eyewashes are not available, or as a supply of immediate flushing fluid to be used before proceeding to the plumbed eyewash

station. Any eyewash solution remaining after use should be discarded. Eyewash bottle solutions should be changed in accordance with the expiry date provided by the supplier.

station. Any eyewash solution remaining after use should be discarded. Eyewash bottle solutions should be changed in accordance with the expiry date provided by the supplier.

All these units require a weekly visual inspection. Follow the manufacturer’s instructions for checking fluid levels and cleanliness in the tank and replacement of the flushing fluid when they expire, and the need to maintain additional flushing bottles. Before purchasing one of these units, contact HSE to determine if this is an appropriate option.

Hand-held Drench hoses/ Dual purpose eyewash/drench hose units at lab sinks

Are supplemental units consisting of a flexible hose connected to a flushing fluid supply and used to irrigate the operator’s eyes, face, and sometimes, the body. To prevent contaminated water from entering a hose from a different source, a drench hose should be installed with a backflow preventer that meets local codes and ordinances.

Are supplemental units consisting of a flexible hose connected to a flushing fluid supply and used to irrigate the operator’s eyes, face, and sometimes, the body. To prevent contaminated water from entering a hose from a different source, a drench hose should be installed with a backflow preventer that meets local codes and ordinances.- These do not replace the need for emergency showers or eyewashes. Health, Safety & Environment (HSE) discourages the use of a deluge hose as an eyewash or body wash. Never rely on sink faucets and hose to replace an eye wash or emergency shower. Drench hoses, sink faucets, or bathroom-type showers are not acceptable eyewash/safety shower facilities; however, they may be useful to supplement eye/face washes and safety showers.

- In the States, the General requirements for dipping and coating operations standard, 29 CFR 1910.124, allows the use of hoses at open surface tanks in lieu of an eyewash and shower. Near

- each open-surface tank containing hazardous liquids, there must be a supply of clean, cold water provided by a 3/4” diameter, 48” or longer hose, with a quick-opening valve. Pressure should not exceed 25 psi. Hoses should be used in conjunction with an eyewash or shower unit unless the hoses meet all the requirements of an emergency eyewash or shower. A backflow preventer should be installed to avoid cross contamination. Note that static rinse tanks may have very low or high pH.

Combination unit (Plumbed) – A unit that has any combination of the emergency shower, eyewash, eye/face wash.

Installation Requirements

Location of Installation

ANSI 358.1-2014 states that an average person covers a distance of approximately 55 feet (16/7 meters) in 10 seconds when walking at a normal pace to reach along an unobstructed pathway from the source of the hazard. An obstacle-free path is crucial since the vision of an injured worker is impaired.

ANSI 358.1-2014 states that an average person covers a distance of approximately 55 feet (16/7 meters) in 10 seconds when walking at a normal pace to reach along an unobstructed pathway from the source of the hazard. An obstacle-free path is crucial since the vision of an injured worker is impaired.

Specific locations for emergency eyewashes and safety showers are best chosen in consultation with HSE. An emergency eyewash/shower station shall be located as near as practical to fume hoods. When chemicals are used in small quantities and the likelihood of exposure is limited, only an eyewash may be required. When quantities used are larger, and significant splashing or spraying may occur, a safety shower shall also be required.

Install equipment near an emergency exit, so emergency-response personnel can more easily reach an exposed employee. Install the equipment in a hazard-free area (and if feasible, near a drainage system to prevent further contamination and excess water accumulation). ANSI also recommends that, for highly corrosive chemicals such as strong acids (pH ≤ 1) or bases (pH ≥ 12), the eyewash and shower unit must be located in proximity to the hazardous activity/ hazard.

ANSI also recommends that, for highly corrosive chemicals such as strong acids (pH ≤ 1) or bases (pH ≥ 12), the eyewash and shower unit must be located in proximity to the hazardous activity/ hazard.- Avoid any location around corners, through closed doors, beyond a partition, or otherwise physically separated from the work environment.

- According to ANSI Z358.1, a door in the pathway is considered an obstruction and the wash area must be installed on the same level as the hazard (i.e. accessing the equipment should not require going up or down stairs or ramps). There shall be no tripping or stumbling hazards in the path of travel to the eyewash. The 2014 ANSI/ISEA standard clarifies that a single step up into an enclosure where the wash is accessed is not considered an obstruction.

Units obstructed by doors. If buildings have their emergency equipment in the hallway or behind doors, a plan should be put in place to improve access to the equipment until it can be moved into the required rooms. Installing a closing mechanism that cannot be locked to impede access (i.e., panic hardware) to the equipment is one strategy for temporarily improving access to the equipment.

Identification. The equipment location is well-lit, identified with a highly visible sign that contains graphical symbols to communicate across language barriers (Appendix B). Signs are white and green to comply with safety instruction and equipment location sign standards (ANSI Z535 Safety Alerting Standards-NEMA, 2011).

Identification. The equipment location is well-lit, identified with a highly visible sign that contains graphical symbols to communicate across language barriers (Appendix B). Signs are white and green to comply with safety instruction and equipment location sign standards (ANSI Z535 Safety Alerting Standards-NEMA, 2011).- No electrical apparatus, telephones, thermostats, or power receptacles should be located within six feet of either side of the emergency shower or emergency eyewash facility. If receptacles are necessary within six feet, they should be equipped with GFI.

- Whenever possible, the floor immediately beneath the eyewash and emergency shower, and to a radius of about twelve to thirty inches, shall be a distinctive pattern and color to facilitate clear access. (Good practices)

Common Installation Requirements

Unit should be assembled in accordance with the manufacturer’s drawing, installed in close proximity to hazard and should be in a location clearly identified and free of obstructions.

Source of Flushing Fluid:

Eyewashes and showers are installed permanently connected to an uninterruptible flushing fluids which can be any potable (drinking) water; preserved water; saline solution; or other medically acceptable solution, the ANSI Z358.1 recommends a preserved, buffered pH-balanced saline solution.

It is critical to maintain the flushing fluid’s pH balance and to not allow bacterial growth.

ANSI/ISEA Z358.1 states that portable equipment “be visually checked to determine if flushing fluid needs to be changed or supplemented.” A bacteriostatic additive can maintain this balance in self-contained eyewash units. In personal wash units, provide a sterile flushing fluid in a closed container that is only opened at the time of use.

Back Flow Prevention Device(s) (supplied by others) should be installed and located in accordance with the local plumbing code.

Back Flow Prevention Device(s) (supplied by others) should be installed and located in accordance with the local plumbing code.

Fast Activation. The ability to turn on in one second or less.

Hands-free Operation. Valves on emergency eyewashes and showers are designed to remain activated until intentionally shut off. Flushing fluid remains on without requiring the use of the operator’s hands.

Water Pressure. The supply water pressure should be at least 30 psi but below 55 (80) psi.

Shut-off Valve. It may be advisable to install a ball-type shut off valve on the water line, upstream of the unit, to facilitate maintenance of the equipment. The shut-off valve is visible, well-marked and. installed and located in accordance with the local plumbing code; provision must be made to prevent unauthorized closure of the shut off valve. Such provision can include removing the handle of the shut off valve or locking the valve in the open position. Only maintenance personnel should be authorised to unlock the valve in the event of leaking or failed shower head valve.

Shut-off Valve. It may be advisable to install a ball-type shut off valve on the water line, upstream of the unit, to facilitate maintenance of the equipment. The shut-off valve is visible, well-marked and. installed and located in accordance with the local plumbing code; provision must be made to prevent unauthorized closure of the shut off valve. Such provision can include removing the handle of the shut off valve or locking the valve in the open position. Only maintenance personnel should be authorised to unlock the valve in the event of leaking or failed shower head valve.

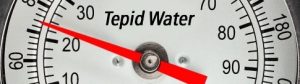

Fluid Temperature of 16-38 C. Tepid or lukewarm water with nominal temperatures of 70°F(21°C) must be supplied to emergency eye/face wash shower. Water temperature from 60/65 - 90/100°F is (15.6/18.3°C – 32.2/37.8°C) considered tepid. Generally, units without a mixing valve or tepid water loop will not maintain a temperature for 15 mins. This makes it difficult for a person to use the unit for the necessary length of time.

Temperatures greater than 100º F have been shown to be harmful to the eyes and can enhance chemical interaction. Where chemical reactions present special hazards

Temperatures greater than 100º F have been shown to be harmful to the eyes and can enhance chemical interaction. Where chemical reactions present special hazards (the material reacts with water or the water temperature accelerates the reaction), a medical advisor should be consulted.

(the material reacts with water or the water temperature accelerates the reaction), a medical advisor should be consulted.

Freezing. Where freezing conditions exist, unit must be protected from freezing. Protect plumbed units from freezing by installing the unit on a wall adjoining a heated space, using electrical heat tracing, or other methods. Protect flushing fluid from freezing in self-contained eyewash units in cold environments by covering the units with heated blankets. Mixing valve(s) (supplied separately) should be installed and located in accordance with the Uniform Plumbing Code. Combination units that are electrically heated (heat-traced) and insulated. These units have a heated enclosure to fully contain and protect both the equipment and the user.

Floor Drain. New plumbed eye/face washes, showers and self-contained emergency showers have a floor drain or drainpipe connected to. Drain location and waste discharge should be installed and located in accordance with the local plumbing code.

Floor Drain. New plumbed eye/face washes, showers and self-contained emergency showers have a floor drain or drainpipe connected to. Drain location and waste discharge should be installed and located in accordance with the local plumbing code.

Emergency showers are installed to meet ADA accommodations where required. ADA accommodations are always required in teaching and instructional spaces (including makerspaces) and in areas where a request for accommodation has been made for a qualified disability.

Alarm Unit. Some manufacturers offer a variety of alarm systems that may be installed in conjunction with their emergency equipment. They serve to alert personnel and summon assistance if an eyewash or shower is activated. We recommend installing an alarm unit with any emergency eyewash or shower unit.

Alarm Unit. Some manufacturers offer a variety of alarm systems that may be installed in conjunction with their emergency equipment. They serve to alert personnel and summon assistance if an eyewash or shower is activated. We recommend installing an alarm unit with any emergency eyewash or shower unit.

Consistent, Balanced Flow

Good design spray heads deliver water in a soft, wide spray rather than a solid, narrow stream. The user receives more water over a wider area than with any other type of outlet head. In an emergency, contaminants are flushed away quickly, gently, and completely.

An engineered flow control located inside each spray head is calibrated to deliver 6.9 or 12.1 litres per minute, at pressures from 20 to 100 PSI. The flow is consistent, and evenly balanced between the spray heads regardless of line pressure。

“Flip Top” Dust Cover

Each spray head is protected against dust and dirt by a “flip top” cover which nests into the top of the outlet head when equipment is not in use. Upon unit activation, water flow swings the cover off the head. The cover is permanently attached to the spray head by a stainless steel pin to prevent removal or loss. Optional stainless steel covers are also available

Easy Maintained Spray Heads

Water often contains dissolved minerals and foreign matter which, over time can build up and clog any spray head. Good spray heads are designed such that all working components are contained within the head itself, making cleaning and maintenance easy.

Each spray head contains an internal filter to remove particles and debris from the water flow. During flushing, the user’s eyes and face are protected against any potential foreign matter which may exist in the water or plumbing lines.

Disposal of Water

The standard does not include any specific provisions regarding the disposal of wastewater. However, designers must give consideration to where wastewater will go. In particular, care must be taken that wastewater that creating a pool in which someone might slip or freeze. Generally, most eyewash, eye/face wash and safety station units are designed with waste connections for connection to drain piping. We recommend that emergency eyewash/facewash and shower units be connected to drain piping. For emergency showers and for other units without wastewater connections, floor drains should be considered/ provided. After an emergency eyewash or shower unit has been used, the wastewater may contain hazardous materials that cannot or should not be introduced into a sanitary sewer. It may be necessary to connect the drain piping from the emergency equipment or floor drain to the building’s acid waste disposal system or to a neutralising tank.

Installation Specification Checklist

This Checklist can serve as a starting point for designing and planning emergency eyewash and shower systems and also highlights the maintenance requirements to ensure your chosen equipment continues to function properly.

All installation parameters shall meet the required standards.

Emergency Showers

Water supply is sufficient to provide at least 75.7 LPM for 15 minutes.

Water supply is sufficient to provide at least 75.7 LPM for 15 minutes.

Hands-free valve activates in one second or less and remains open until manually closed.

Shower delivers 75.7 liters (20 gallons) of water per minute for 15 minutes in the required pattern.

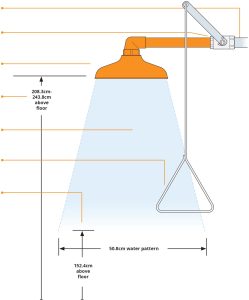

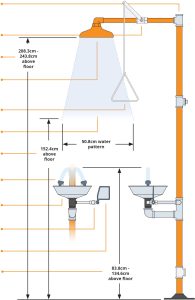

Shower head should be located between 208.2 cm (82 inches) and 243.8 cm (96 inches) from the surface on which the user stands

Center of the water spray pattern is at least 40.6 cm (16 inches) from any obstruction.

Easily located, accessible manual actuator (triangle pull lever) is no more than 173.3 cm (69 inches) above floor. The manual actuator is free from obstruction for 18 to 24 inches in most directions.

At 152.4 cm (60 inches) above the floor, the water pattern is at least 50.8 cm (20 inches) in diameter. With the shower valve in the fully opened position

If provided, shower enclosure has a minimum diameter of 86.4 cm

|

○ |

Unit should be connected with a recommended minimum 1” IPS line to a tepid, clean water source capable of supplying 30-80 PSI flowing pressure for a minimum of 15 minutes. If shut-off valves are installed inline, provisions should be made to prevent unauthorized shut off |

|

|

Most emergency showers include Opaque “modesty curtains” to encourage the affected person to remove contaminated clothing rapidly – a critical step after exposure to harmful materials. |

Eye or eye/face wash

Controlled, low velocity flow completely rinses both eyes simultaneously and face and is not injurious to user.

Controlled, low velocity flow completely rinses both eyes simultaneously and face and is not injurious to user.

is sufficiently high to allow user to hold eyes open while rinsing.

Spray heads are protected from airborne contaminants. Covers are removed by water flow.

Unit delivers at least 11.4 liters of water per minute (3 GPM) for eye/face washes for 15 minutes.

Eyewash unit delivers at least 1.5 liter per minutes (0.4 GPM) of flushing fluid for 15 minutes.

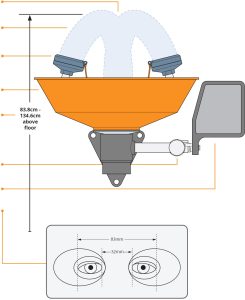

Water flow pattern is positioned between 83.8 cm and 134.6 cm (33 and 53 inches) from the floor and at least 15.3 cm (6 inches) from the wall or nearest obstruction.

Hands-free stay-open valve activates in one second or less.

Valve actuator is easy to locate and readily accessible to user.

Unit washes both eyes simultaneously. Water flow covers area indicated on Guardian test gauge at no more than 20.3 cm above spray heads.

With the eyewash valve in the fully opened position and using a test gauge, the spray pattern should meet required pattern per ANSI Z358.1.

|

|

If they are installed mounted on a counter, they are mounted within 8 inches of the front edge of the lab bench to allow the eyes to be placed in the path of water by simply standing near the unit. There is minimal reaching, bending, stretching or contorting required to reach the eyewash |

|

|

Emergency eyewash nozzles are protected from airborne contamination. Whatever means is used to afford such protection, its removal will not require a separate motion by the operator when activating the unit.

|

Drench Hose Note: Do not exceed 90 PSI working pressure. Inspect at least monthly for wear, abrasion, loss of flexibility or loosening of end connections

Emergency Eyewash/facewash Shower Unit

Water supply delivers required flow when shower and eye or eye/face wash are operated simultaneously.

Hands-free stay-open valve activates in one second or less.

Hands-free stay-open valve activates in one second or less.

Height of water column is between 208.3 cm and 243.8 cm above the floor.

Shower delivers 75.7 liters of water per minute for 15 minutes in the required pattern.

Easily located, accessible actuator is no more than 173.3 cm above floor.

Center of the water pattern is at least 40.6 cm from any obstruction.

At 152.4 cm above the floor, the water pattern is at least 50.8 cm in diameter.

Spray heads are protected from airborne contaminants. Covers are removed by water flow.

Unit delivers at least 11.4 liters per minute (for eye/face wash or 1.5 liters per minute (for eyewash) for 15 minutes.

Hands-free stay-open valve activates in one second or less.

Valve actuator is easy to locate and readily accessible to user.

Water flow pattern is positioned between 83.8 cm and 134.6 cm from the floor and at least 15.3 cm from the wall or nearest obstruction.

Training and Its Proper Use

It is important that we should learn how to operate your safety equipment before accident happens. If you work with hazardous chemicals, know the location and how to use the nearest eye wash and emergency shower.

- Eye/face washes and emergency showers are easy to operate. Most equipment is designed for hands-free operation with either paddles, levers, or a pull-lever.

- To turn off, simply reverse the action required to activate it.

Training

- Laboratory staff and students should receive emergency eyewash shower training during

- Laboratory safety and chemical safety training, and

- Laboratory safety orientation on the practical activation procedure for eyewash and shower use during an emergency

- Provided by Laboratory or Area Safety Coordinator, or Department of HSE.

- Laboratory staff responsible for emergency eyewash shower management

- Induction training on how to perform weekly/ monthly flushing and maintain minimum performance requirements for eyewash and shower equipment.

- Provided by Laboratory or Area Safety Coordinator, or during annual conformance testing or workplace safety inspections.

Simply installing emergency equipment is not sufficient to assure worker safety. All individuals who are at risk of exposure to hazards must receive training on the proper use and location of emergency eyewash and shower. Training may be conducted by responsible laboratory supervisor to ensure that their laboratory personnel are adequately trained.

Also, lab supervisors should develop a response plan to be used in the event that an accident does occur. The focus of the response plan should be to provide assistance to the injured worker as quickly as possible.

Know the location of emergency eyewash shower

- Locate your nearest emergency eyewash and shower. An emergency eyewash and shower must be available within 10 seconds of unobstructed travel from where hazardous materials are used.

- Keep the path clear and unobstructed to your eyewash shower.

- Be aware of electrical hazards. Always keep energized electrical equipment away from eye/face washes and emergency showers.

Don’t Hesitate

- The first few seconds after exposure to a hazardous chemical (especially a corrosive chemical) are critical. Delaying treatment, even for a few seconds, may result in irreparable eye or tissue damage. Don't hesitate!

- Note: Some outdoor eye/face washes or emergency shower may run discolored (rusty) water for a few seconds. Don't hesitate to use them immediately when needed.

- Drains are rarely designed into floor plans to accommodate eye/face wash stations. Never let that stop you from using the equipment when needed. Call Facilities Management at (xxx) xxxxxx as soon as possible to collect water where drains are not installed.

Emergency eyewash/facewash and shower operation

Use the emergency eye/face wash immediately if your eyes or faces or body parts are exposed to a hazardous chemical.

Without delay, make your way to the nearest eyewash station, immediately flush eyes/face or affected body parts for at least 15 minutes

Without delay, make your way to the nearest eyewash station, immediately flush eyes/face or affected body parts for at least 15 minutes- Keep the eyes open (Hold eyelids open) with your hands to fully irrigate the entire eye. Rotate the eyeballs in all directions to remove contamination from around the eyes. An injured person may need help holding the eyelids open.

- Protect the unaffected eye/ body parts from inadvertent secondary contamination.

In using the shower, remove contaminated clothing, jewellery, and shoes during flushing. Don't let modesty slow you down. Every second counts. (Use a clean lab coat/Tyvek coverall/ clean clothing or even fire blanket to provide the victim with privacy and warmth.) Seek assistance from any other lab personnel in flushing the affected area or removal of clothing.

In using the shower, remove contaminated clothing, jewellery, and shoes during flushing. Don't let modesty slow you down. Every second counts. (Use a clean lab coat/Tyvek coverall/ clean clothing or even fire blanket to provide the victim with privacy and warmth.) Seek assistance from any other lab personnel in flushing the affected area or removal of clothing.

- If an assistant is available, have the SDS reviewed for any further first aid requirements for the hazardous material involved.

- Call Poison Control Center at (xxx) xxxx- xxxx for advice, then seek medical attention immediately.

- Have someone bring or send the Safety Data Sheet for the chemical to the emergency unit of hospital/ doctor.

- Once the emergency has subsided, notify the research or lab supervisor of the accident/ incident/ injury.

- Report the injury or exposure. See What to Do if a Work-Related Injury, Illness, or Exposure Occurs.

- Immediately flush the affected area with copious quantities of water for at least 15 minutes. Without delay, make your way to the nearest safety shower and activate

- When an eye injury occurs, have an ophthalmologist or medical doctor examine the eye as soon as possible. It a victim experiences blurred vision partial loss of vision, double vision, or sharp pain in the eye after an incident, take the victim to an emergency room immediately and consult an ophthalmologist.

Commissioning, Compliance Testing and Regular Flushing and Maintenance

All new emergency eye/facewash shower equipment must meet the installation and operation guidelines in ANSI Z358.1. A full test to determine if it meets these guidelines must be performed after installation. Contact HSE to set up a time to witness/perform this test.

Emergency equipment must also be regularly maintained and tested at least annually to verify that its performance is in working order, and also in compliance with the standard.

A testing team will be designated by the HSE staff. All members of the team shall undergo hands-on training by experienced EH&S personnel of HSE.

Commissioning, Testing and Reporting of New Installations

Proper operation of the equipment, in accordance with the specifications of the ANSI 358.1 standard and the requirements of HKUST(GZ), shall be demonstrated prior to renovation project closeout and facility moving-in or occupation.

New emergency eye/face wash shower must be reported to HSE by laboratory or campus facility managers after installation. The includes equipment installed by LS and outside contractors.

To ensure eye/facewash and safety shower compliance, plumbed and portable wash units should be tested for the following:

- Flushing duration -

Units should provide at least 15 minutes of hands-free flushing immediately and thoroughly after exposure, using an ample supply of clean fluid under low pressure. - Fluid flow and pressure

The fluid pressure must be at a velocity low enough not to injure the user: a minimum of 0.4 gallons (1.5 liters) per minute for eyewashes; 3 gallons (11.4 liters) per minute for eye or face washes; and 20 gallons (75.7 liters) per minute for showers. Closely regulate fluid pressure in eyewash stations to avoid damaging tender eye tissue.

Regular (Weekly/Biweekly) Flushing and Check of Plumbed Eye/face washes and Emergency Showers

Acanthamoebae are commonly found in eyewashes and can cause severe eye infections when introduced into traumatized eyes. Pseudomonas (which can cause septicemia or “blood poisoning”) and Legionella (which can cause Legionnaires’ disease, a severe form of pneumonia) bacteria may also be present.

Regular (Weekly/biweekly) flush and checks of plumbed eyewashes and showers are a key element to ensuring its proper function. This helps clean out any rust, scale deposits or any sedimentation, prevent a build-up of biofilm or debris in the spray heads and along pipeline, and minimize microbial contamination. Eyewash flushing for at least three minutes has been suggested to reduce amoebic and bacterial growth. Ideally, the units should be flushed for the length of time it takes to replace the water in the unit and the piping from the unit to continuously running water.

This is the responsibility of the supervisors of the laboratory or workspace. Lab supervisors should delegate a responsible person for inspecting and activating the emergency eyewash and shower station weekly.

Logistics may prevent individual laboratory from performing weekly activations of emergency showers as specified in ANSI Z358.1. When weekly activation/ flushing is feasible, the flushing should also:

- Verify the access to the emergency eye/face wash and shower is unobstructed with good clearance maintained. including countertop-mounted eye washes. Contact the laboratory supervisor and arrange for immediate clearing of the obstruction.

- Verify the tag for the annual conformance inspection/testing date. If nearing the due date, contact HSE or Laboratory Services to arrange for the testing or preventive maintenance inspection.

- Visually inspect the eyewash and shower to ensure that there are no broken parts, leakage, accumulated dirt, rusty parts, missing lever, or other visible signs of equipment damage, etc.

- Verify that eyewash nozzle protective covers are properly positioned, clean and intact. Upon activation, nozzle covers should automatically disengage from the nozzle.

- Check that the spouts are clean, and the bowl and/or sink drains are free of trash.

- Activate the eyewash/ shower for approximately 2-3 minutes; check that the flushing fluid is provided is clean, effective and continuous. The water should begin to flow from both nozzles within 1 second with equal pressure or the shower head with adequate pressure.

- Check for any leaks while all valves are in the closed position. Verify that all valves stay in the open position upon activation.

- If flow pattern of the eyewash is uneven, suspected of pressure of too high or too low, use the eyewash testing gauge to test for the pattern. The flushing fluid should cover both inside and outside line when the gauge is lowered no more than 1.5 inches below the fluid peak.

- If the unit does not operate as required; the temperature is too hot or cold; water does not turn off; defective lever or handle; tag the unit “out of service” and contact Laboratory Services for repair.

- If there is no problem, mark the date and initial the EWS Weekly Flushing Records Tag (Appendix C) and affix it to the wall or the equipment. Flushing record tags are available free of charge from HSE central warehouse.

- Ensure that problems identified during the activation are resolved as soon as possible. If the unit is found to be non-operational, and there are no other units in the space as back-up, all work with hazardous material that require an eye/facewash or shower must cease until the unit is repaired.

For self-contained eyewash/facewash unit, the flushing fluid should be replaced according to the schedule provided by manufacturer.

Equipment and Supplies

Prior to activation of emergency shower unit, the shut off valve to the unit must be located and clearly labelled. Turned closed several times, then opened completely to ensure that it is working properly.

- Ladder, transport vehicle

- A 250 L (55 gallon) drum/ cart with spray control sleeve/ curtain

- Bucket (2), 100 L plastic drum

- Lab coat, eyewear, gloves

- Eyewash gauge

- Portable radio, flashlight,

- testing record tags, out of service cards,

- shower trip buckets, sponge mop, paper towels.

Annual Conformance Testing and Maintenance

Plumed eye/face washes, emergency showers, and supplemental drench hoses must be tested and maintained annually to ensure conformance with installation and operation guidelines in ANSI Z358.1. The testing is required to be performed by HSE personnel.

The eyewash and shower station must bear a testing tag indicating the date of last conformance testing. If the testing is not current, inform HSE to verify the performance. Results from annual conformance testing are also available online to laboratory or facility designated supervisors (via the Room Safety Equipment RSE website).

Preventive maintenance inspections can be performed at the same time by Laboratory Services semi-annually to check for problems such as valve leakage and clogged lines. Put down the date of maintenance inspection on the PM inspection tag. The procedure for conducting annual inspection should follow the manufacturer’s installation/instruction manual (if applicable) and the ANSI Z358.1-2014 standard. Laboratory Services staff should refer to the standard for the preventive maintenance inspection parameter requirements. A guidance document checklist for the Semi-annual Preventative Maintenance inspections can be found in Appendix B

The Eyewash/facewash and Shower Station Conformance Inspection is based on the Checklist (Appendix x). It should be filled in with the date of inspection and the initials of the inspector.

- Verify the access to the emergency eye/face wash and shower is unobstructed with good clearance maintained. including countertop-mounted eye washes. Contact the laboratory supervisor and arrange for immediate clearing of the obstruction.

- Visually inspect the eyewash and shower to ensure that there are no broken parts, leakage, accumulated dirt, rusty parts, missing lever, or other visible signs of equipment damage, etc.

- Verify that eyewash nozzle protective covers are properly positioned, clean and intact. Upon activation, nozzle covers should automatically disengage from the nozzle.

- Check that the spouts are clean, and the bowl and/or sink drains are free of trash.

- Activate the eyewash/ shower for at least 3 minutes at the same time; check that the flushing fluid is provided is clean, effective and continuous. The water should begin to flow from both nozzles within 1 second with equal pressure or the shower head with adequate pressure.

- Estimate the volume of eyewash/facewash flushing water and calculate the flow rate.

- Estimate the volume of shower flushing wate and calculate the flow rate.

- Check for any leaks while all valves are in the closed position. Verify that all valves stay in the open position upon activation.

- Use the eyewash testing gauge. The flushing fluid should cover both inside and outside line when the gauge is lowered no more than 1.5 inches below the fluid peak.

- The temperature should reach a tepid range within the first minute. If unsure if the temperature of the water is acceptable, inform Laboratory Services for checking.

- If either eyewash/facewash or shower of the unit does not operate as required; the temperature is too hot or cold; water does not turn off; defective lever or handle; tag the unit “out of service”, inform the lab supervisor and contact Laboratory Services for repair.

- If the unit passes the test, mark the date and initial the Inspection Form.

- Scan the QR code to update the inspection/flushing/ maintenance record database.

- Ensure that problems identified during the activation are resolved as soon as possible. Inform the laboratory supervisor. If the unit is found to be non-operational, and there are no other units in the space as back-up, all work with hazardous material that require an eye/facewash or shower must cease until the unit is repaired.

For self-contained eyewash/facewash unit, the flushing fluid should be replaced according to the schedule provided by manufacturer.

Repair and Maintenance of Emergency Eyewash and Shower Equipment

Corrective actions must be performed when deficiencies are noted by any personnel at any time.

When an emergency eyewash station or safety shower is out of service, non-functional, or did not meet requirements, repair of the equipment should not be delayed. Inform the laboratory supervisor. The work order for repair or replacement should be submitted to Laboratory Services by sending an on-line service request form to the Service Desk at servicedesk@ustgz.ust.gz.cn. Repair procedures should follow the manufacturer’s installation/operation manual.

If use of the equipment is not possible tag the unit “DO NOT USE”. In the event that a laboratory is without a proper functioning eyewash, a portable eyewash station or equivalent must be available if work with hazardous materials cannot be delayed.

Disposal of Flushing Fluids

Properly dispose of wastewater. Do not allow it to enter a domestic wastewater treatment system if the flushing fluid contains hazardous material. In such cases, waste water can be connected to “laboratory waste water system” which leads to a neutralization treatment system.

FAQs

Are personal eyewashes (squeeze bottles) able to be installed in lieu of suitable eyewash facilities?

Personal eyewashes do not meet the criteria of plumbed equipment. These units are only supplemental.

Where does the suitable eyewash/shower have to be located?

Emergency equipment must be readily accessible in areas where corrosive or injurious materials are used. They should be as close as possible to the area where a potential exposure can occur. At a maximum those work areas must be within 10 seconds of the emergency flushing equipment. ANSI defines the normal speed of travel as 55 ft per 10 seconds for an average person. Keep in mind that in an emergency, it may take longer than 10 seconds to travel this distance.

The route to the emergency equipment must be unobstructed. Doors are obstructions.

All the emergency showers are located in the hallway. What do I do?

Doors are obstructions in the path to the showers. It is important to improve accessibility to the emergency equipment. There must be a plan in place to improve accessibility to those units.

Does installation of a safety shower require a floor drain?

Some local plumbing code requires that floor drains are installed while it is prohibited in some codes. and a trapped and vented receptor and shall comply with ANSI Z358.1.

Supply of water

Emergency showers and eye wash stations within a building shall be provided with potable water

Can I install an eyewash on a faucet?

Emergency eye wash stations is not recommended to be used on a faucet spout as standard eyewash unit.

Also, most facet mounted eyewashes cannot be turned on in one motion and there is a difficulty of setting a proper temperature that is not injurious to the eyes.

Who can install or modify eyewash and shower equipment?

Licensed plumbers must be used to modify and install equipment on campus.

What is a corrosive substance?

Substances that cause visible destruction of or irreversible alterations in living tissue by chemical action at the site of contact are considered corrosive. Acidic materials with pH less than 4.0 or bases (alkaline) with pH greater than 9.0 are considered corrosive. Common corrosives include strong acids, strong bases, and concentrated solutions of weak acids or bases. There are other compounds that are corrosive to living tissues and are less obvious (Citric acid, calcium oxide, concentrated hydrogen peroxide, sodium hypochlorite, acid anhydrides, alkylating agents, some organics, etc.). The container label and section 2 (Hazards Identification) of a chemical’s Safety Data Sheet can be used to determine if a chemical is corrosive. Some substances may be classified as acids or bases but their actual level of corrosiveness is low when in contact with the body or eyes and would not be considered likely to cause injuries. These can include hand soaps and some food items like vinegar or lemon juice.

What is an injurious substance?

For the purpose of preventing adverse effects to the health and safety of a person, an injurious substance is one that is dangerous by eye or skin exposure. Materials that are absorbed through the skin and can cause additional harm to the body are included here. For example, methylene chloride and many other organic compounds are classified as injurious by dermal exposure. Other hazards must be evaluated based on their risk of exposure and severity of the consequence (e.g., use of pyrophoric, use of DMSO as a carrier solvent). Potentially infectious materials are also considered injurious and must be flushed immediately from eyes (mucous membranes).

Still uncertain about emergency flushing facility is required.

If the need for emergency eye/face wash and shower is not clear based on the above definitions, a risk assessment can be performed to determine the potential and severity of a consequence after exposure to the hazard. Contact HS&E to help to perform this risk assessment. Exceptions may be granted in cases where emergency equipment installation and use cause a more significant hazard than the chemicals present (e.g., rooms that have electrical hazards). In these cases, there still must be a means of flushing chemicals from the body and eyes in an adjacent location.

Related Training Materials

Related Training Videos&Photo